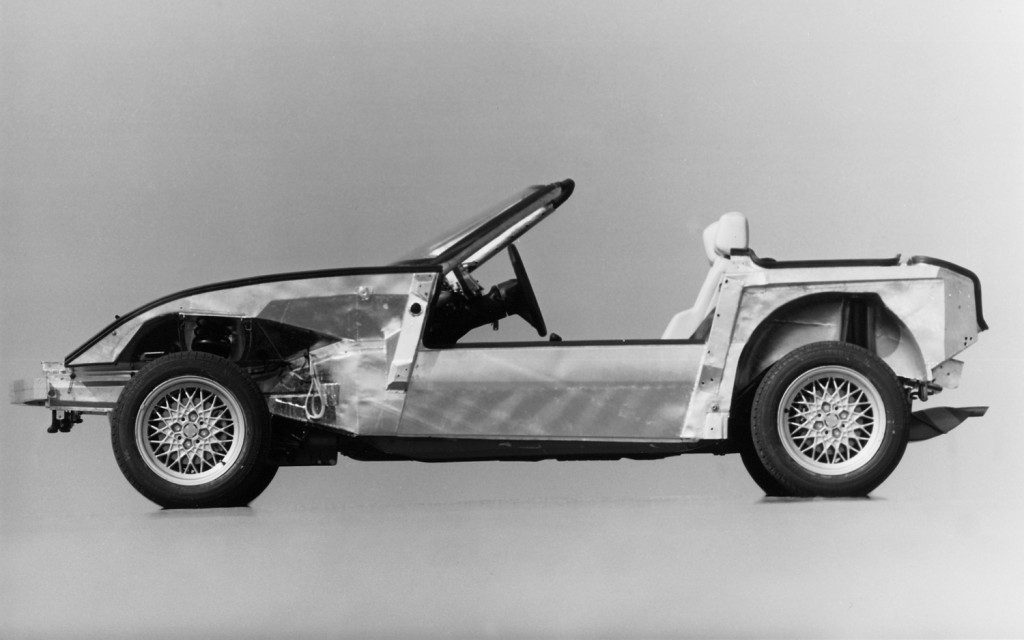

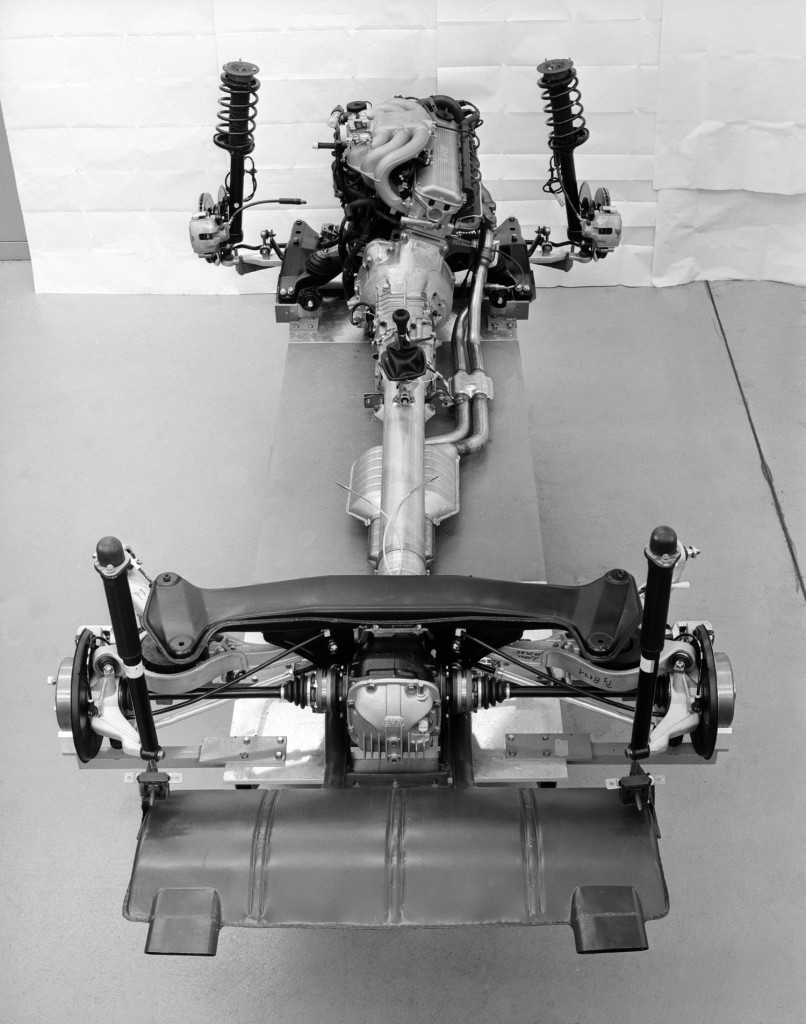

BMW's first Two-seater roadster since the 507 in 1959, using the engine and transmission from the E30 325ix, mounted in a specially designed chassis made from galvanised steel. The sports body is made from various types of composite resin panels also bolted to the chassis. The front suspension uses mainly 325i components but with a wider track. A multi-link axle comprising two transverse control arms and one longitudinal control arm, dubbed the 'Z-axle', shorthand for 'centrally guided, spherical double-wishbone axle' rather than a reference to the new name. The kinematic arrangement of the three control arms ensured excellent directional stability as well as effective anti-squat and anti-dive, endowed the Z1 with go-kart-like handling.The most distinctive features of the body are the electrically powered doors, which in the open position drop down into the side sills, this creating the ultimate 'open car' when the soft top is lowered underneath its' flat cover.

For more on the history and construction, try the new ZIKI